29

2020

-

10

Twin-shaft Vertical Kneader Analysis

Keywords:

twin-shaft,Kneader,Kneader

Source: internal company

Twin-shaft Vertical Kneader Analysis

1. Hybrid physical model

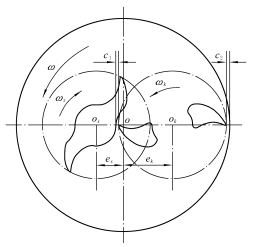

Fig 1: Radial assemble structure of mixing kettle Fig 2: Effective mixing zone in mixing kettle

The stirring system of VKM-5 Twin-shaft differential vertical kneader consists of mixing kettle, solid paddle and hollow paddle. The inner wall of the mixing kettle is a hollow thermal insulation layer, which is filled with 30 ℃ constant temperature water provided by the water supply system. The hollow paddle and the solid paddle are vertically installed. The eccentricity of the center of the mixing kettle with the two stirring paddles is ek and es respectively, and ek = 2es. The rotation speed of hollow propeller is k, and that of solid propeller is s, and k=2s. The revolution speed of the two paddles is, the rotation revolution speed ratio k/=15. The diameter of the mixing kettle D=200mm, the kneading gap between the hollow paddle and the solid paddle is C1=3mm, and the kneading gap between the solid paddle and the wall of the mixing kettle is C2=3mm, as shown in Fig. 1. In the stirring process, the mixing working area consists of three areas: the kneading area (area I) formed by the hollow paddle and the solid paddle, the near-wall area (area II) formed by the hollow paddle and the mixing kettle wall, and the bottom area (area III) formed by the bottom surface of the double paddle and the mixing kettle bottom. As shown in FIG. 2, in these three mixing working areas, hollow paddle and solid paddle blades push solid propellant materials to interact with the tank wall and tank bottom of the mixing tank to promote uniform mixing of materials.

2. Flow field characteristics

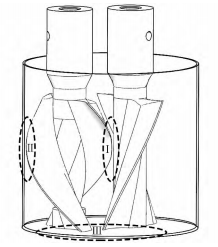

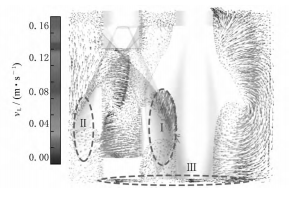

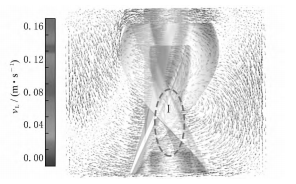

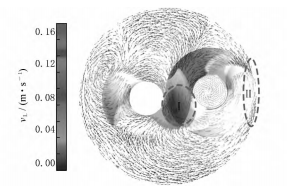

Fig 3: Velocity vector field in Y-direction section Fig 4: Velocity vector field in X-direction section Fig 5: Velocity vector field in Z-direction section

2.1 Macroscopic flow field

The actual working speed of the double-axis differential vertical kneader is 30-90r/min, and the calculation results of the medium speed of 60r/min are taken for analysis and research. The stirring paddle is not centrally symmetrical, and it is difficult to show a smooth and complete picture in a single view. Figures 3 and 4 show the axial velocity vector fields in the Y and X directions of the mixing kettle (vL is tangential velocity), and Figure 5 shows the velocity vector fields in the Z direction of the mixing kettle. Because the curved surface of the stirring paddle is very irregular, the whole flow field is more complex. Axial flow, tangential flow and radial flow coexist. Solid propellant materials form axial and radial circulating flows inside the mixing kettle and roll up and down. The maximum axial velocity and the larger radial velocity in the kneading zone of the two blades, The shear action is strong, Is the most effective mixing region, i.e. Effective mixing region I, The scraper region between the hollow paddle and the mixing kettle wall has the largest tangential velocity and the larger axial velocity, It is the effective mixing zone II. The bottom zone formed by the bottom of the hollow propeller, the solid propeller and the bottom of the mixing kettle has the largest radial velocity and the larger tangential velocity. It is the effective mixing zone III. Due to the high viscosity of the solid propellant, the fluidity in other zones is poor in time, and the mixing is mainly carried out by molecular diffusion, with the lowest mixing efficiency.

2.2 Pressure Field Analysis

The rotation and revolution of hollow paddle and solid paddle are the power sources to promote the uniform mixing of solid propellant materials. The shear and tensile effects caused by the movement of the two paddles make a certain pressure difference in the mixing kettle. The pressure difference is the main driving force to drive the material movement, which will directly affect the velocity distribution and power consumption of the flow field in the mixing kettle.

In the process of blade movement, the gap between the two paddles in the kneading zone is the smallest, the shear effect on solid propellant materials is the strongest, and the pressure on the material facing the hollow paddle and the material facing the solid paddle in the kneading zone is the largest, which will help to push the material to move along the axial and radial directions and form axial and radial circulation flow. As a result, that pressure on the material in the twin-paddle knead zone is also the largest, up to 1.46 x 105Pa, The pressure field gradually decreases along the axial direction, It is rapidly reduced to-2.3 x 104Pa along the negative direction of the axial direction, And forms an axial flow, This will facilitate the stretching material to fill the kneading zone more quickly, Accelerate the rapid and uniform mixing of the materials in the whole mixing kettle, the blades have the maximum tangential speed in the near-wall area of the hollow propeller, and produce tangential and axial extrusion on the materials. The pressure field is-1.08 x104Pa in the opposite direction along the axial direction. The negative pressure area will continuously stretch the materials at the bottom of the near-wall area to fill the near-wall area for tangential and axial shear mixing.

The pressure in the bottom area of the kettle is less than that in the kneading area and the near-wall area, and the pressure is mainly concentrated at the two tips of the hollow paddle. The maximum pressure generated by the movement of the hollow paddle near the material facing surface of the kettle wall is 2.6 x104Pa, which can produce a certain tangential shear effect with the stationary kettle bottom. The gap between the back material surface of the hollow paddle near the kettle wall and the double paddle is-3.85 x104Pa, which can stretch the material and provide the space and channel required for circulating flow in the mixing kettle.

Related news

2024-04-12

2024-03-29

2024-03-07