18

2020

-

08

Powder Mixing Technique

Keywords:

powder,mixing,mixing,technique

Source: internal company

Mixing is a process in which particles with different physical and chemical properties are evenly distributed in space. It is widely used in food, medicine, materials (especially powder metallurgy), plastics, chemical fertilizers, buildings and many other fields. It is very important to mix the powder efficiently, and good mixing condition is the guarantee of product quality.

1. Several main factors affecting the mixing effect

The factors affecting powder mixing may be summarized into four aspects: particle properties, mixer performance, process parameters and mixing environment. Experience shows that the change of any element may have obvious influence on the mixing process and mixing effect.

Whether the particles can be effectively mixed is often measured by "compatibility". Good compatibility is one of the key factors to realize uniform mixing. If the two kinds of particles are incompatible, the ability to mix with each other and maintain stable spatial distribution is small, the separation tendency is strong, and the final mixing uniformity is not high and fluctuates greatly. If the two are compatible, that is, the physical properties of the powders are consistent or similar, a differential system with homogeneous phase or extremely small phase domains can be formed, which is conducive to improving and maintaining the mixing uniformity. Powder mixing is a complicated process affected by many factors. In the past, when people studied the mixing problem of powder, they often simplified the mixing process appropriately and recognized the main characteristics of the mixing process by determining the influence of a single factor on the mixing effect.

2. Mix process and mix mechanism

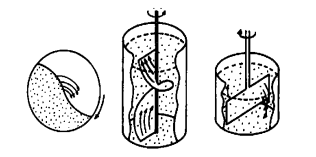

At present, it is generally believed that the mixing mechanism of powder mainly includes diffusion, convection and shearing. As shown in Fig. 1, diffusion refers to the process in which a single particle enters the powder mass. The powder of the continuously rotating object surface is continuously dispersed, unfolded, mixed with each other, infiltrated and mixed at the edge. Convection refers to the movement of adjacent powder masses from one place to another in the material; Shear means that the material is continuously divided or the powder flows on the slip surface. The relative movement between particles forms several slip surfaces on the material surface and mixes and blends with each other.

Diffusion Convection Shear

The actual mixing process is often the joint action of several mixing mechanisms. Different powders in different mixers and at different rotating speeds have different mixing movement forms and different mixing effects. The mixing process of powder can be roughly divided into three stages: (1) convection mixing stage, the mixing progress is very fast; (2) In the stage of convection and shear interaction, the mixing speed in this stage is slower than that in the stage of convection mixing. (3) The diffusion mixing stage is in the equilibrium of mixing and separation, and the mixing uniformity fluctuates up and down near a certain average value.

3. Numerical simulation of mixing process

The numerical simulation of particle flow can be divided into three types according to different models: continuous type, kinetic energy theory type and discrete type.

The continuous type ignores the discrete properties of particulate matter and assumes it as a continuum that obeys the laws of mass conservation and momentum conservation. Therefore, the fluid motion equation (combining energy, mechanics and heat transfer equations) is used to describe the behavior of particles. Continuity models are transformed from soil plasticity and fluid mechanics. Some continuity models also introduce microstructure parameters, which can be used to describe the distribution state and expansion phenomenon of solid debris of particulate matter. Most of these models are used for telling flow dominated by Coulomb friction or collision, and there are also models combining these two behaviors.

The kinetic energy theoretical model is established according to the similarity between the contact of particles in particles and the collision of molecules in dense gases. These models can be used to describe the motion of particles under certain specific conditions, such as stirring the surface of particles, and the velocity fluctuation is similar to Maxwellian distribution, in combination with the energy dissipation equation characterizing the characteristics of particle flow. The conservation equations of mass, momentum and kinetic energy of particulate matter are established by statistical average method.

Discrete models have many forms according to different rules describing particle motion. Discrete type includes: Monte Carlo method based on probability and statistics law; The unit automatic operation method adopting deterministic law; And particle dynamics derived from the first law. With the successful application of molecular dynamics model in gas and liquid systems, Youlide supports particle dynamics.

Related news

2024-04-12

2024-03-29

2024-03-07